Differences between galvanization and other decorative techniques

What for other decorations is a problem, becomes a strong point value added for galvanizing!

- Cold touch effect

- Resistant to abrasion

- Stress test

- Resistance over time and maintenance of color

are just some of the peculiarities that distinguish our galvanizing process.

Galvanizing is not a film; it is something totally linked to your packaging.

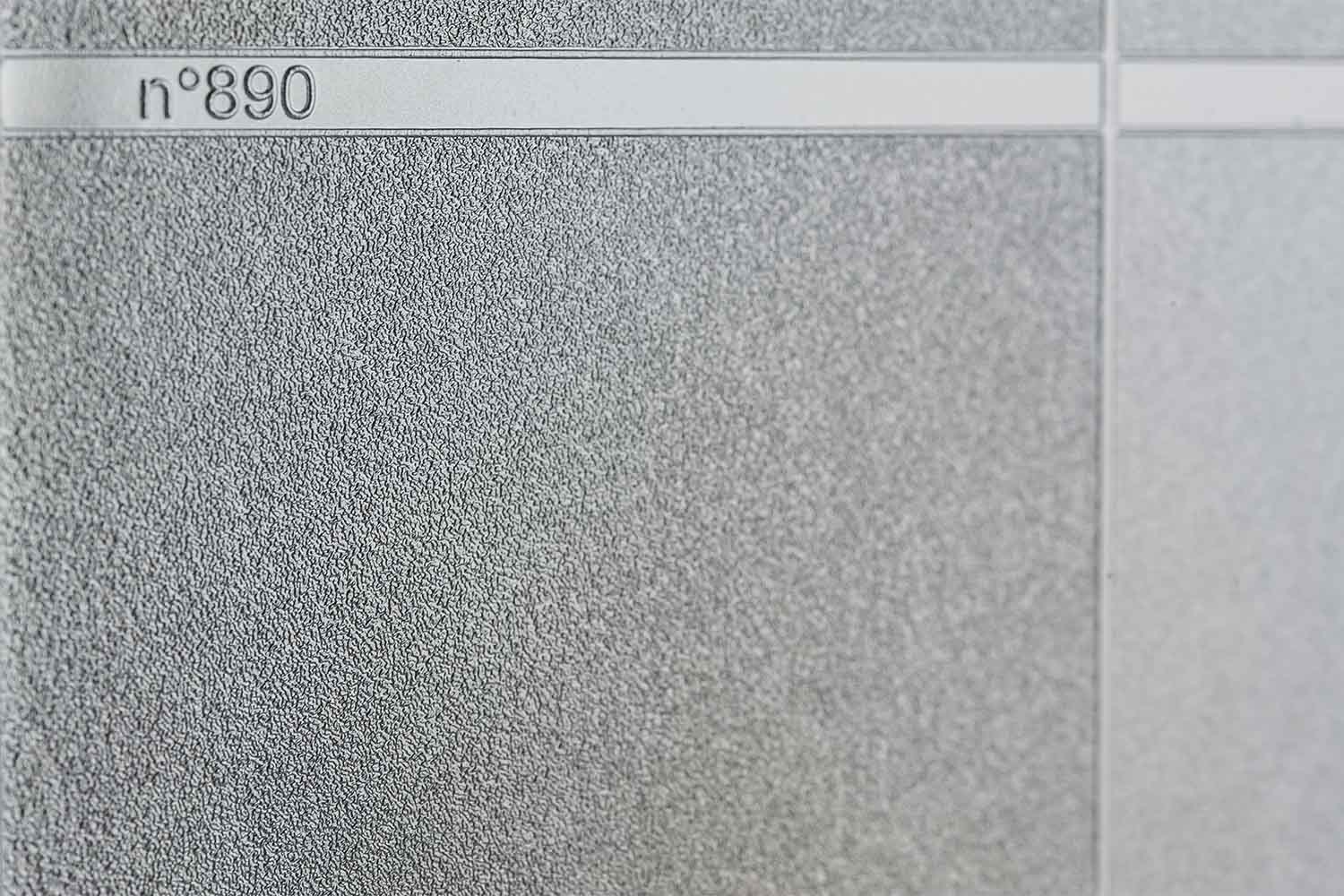

Abrasion

Resistance to abrasion

The problem of abrasion occurs especially when the piece is manipulated and over-used.

Each galvanized piece has a high degree of abrasion resistance that prevents the treatment from being removed.

Plated parts can come into contact with thousands of pieces without deteriorating, aspect which can not be done with other processing techniques.

Resistance test

Stress test

Each galvanized piece can be successfully tested to resistance such as:

- synthetic sweat

- salt spray test

- resistance to perfume

- rapid aging test

- wet heat resistance

- adhesion texts according to ISO 2409

Dowload the results of the wet heat resistance test

Resistence to reagents

- Acidic, alkaline, alcoholic substances

- Decolorising and staining agents

To be underlined that galvanizing treatment is widely used and diffused in the automotive market thanks to the technical performance that is able to provide.

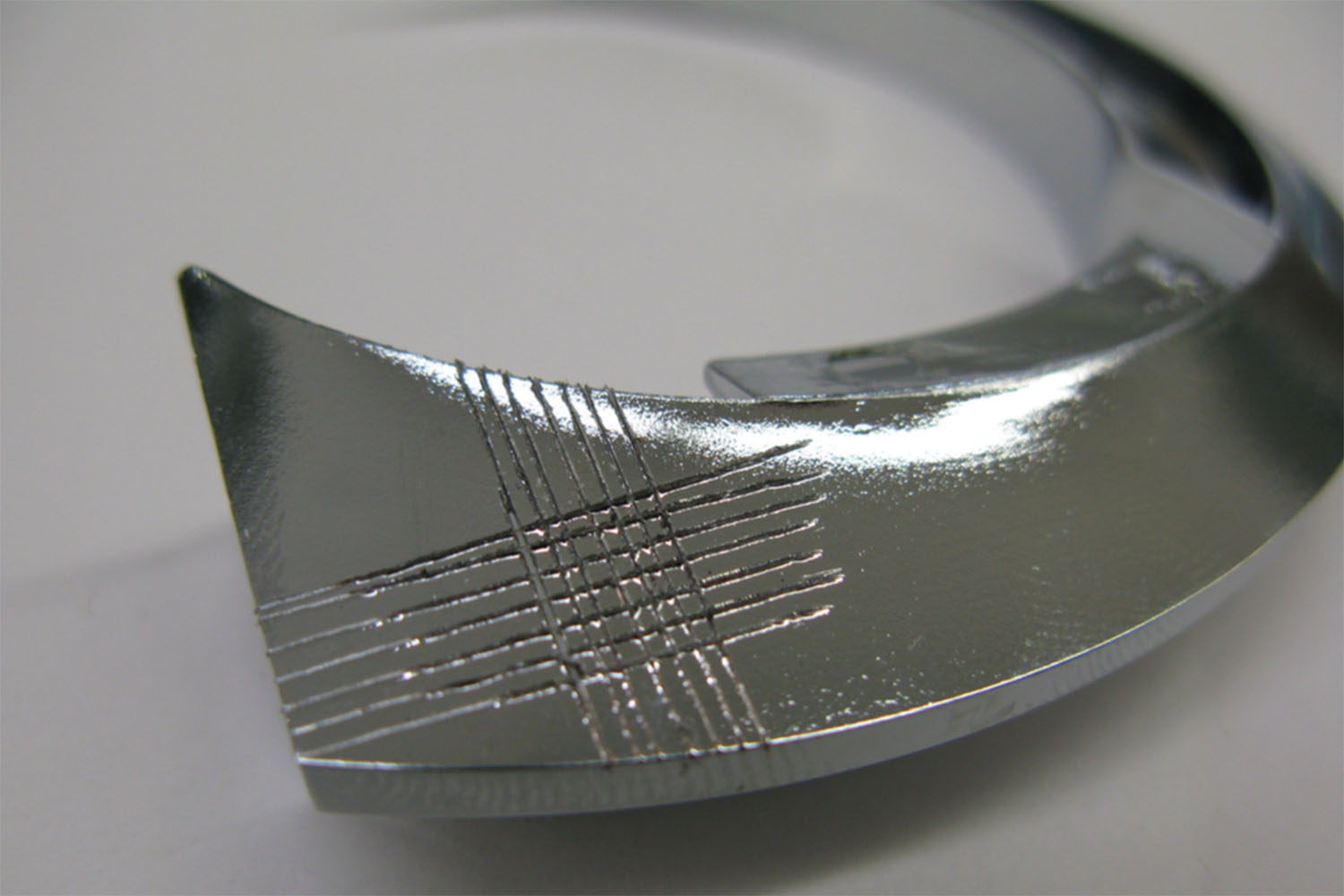

Cold touch effect

Cold touch effect

Galvanizing, unlike the painting processes that leave the piece hot and immediately attributable to the plastic, is the ONLY finishing treatment that can transform and make COLD TO THE TOUCH a piece of plastic..

The COLD TOUCH EFFECT gives an immediate feeling that plated part has been produced with real forged metal wich brings to the final product a high added value, incomparable and unreachable with any other painting process and with production costs infinitely lower than one piece metal.

Call directly +39 035 847060 for technical clarification, or send us an email