Sustainable Company

Cromoplastica CMC is extremely aware of the huge urgency of CO2 emission reduction into the atmosphere, main cause of climate changes which are seriously damaging our planet.

For this reason, since several years, we are deeply focused in reducing as much as possible CO2 emission during all steps of our production.

Italian and European IPPC IED and AIA authorizations and ISO 14001:2015 and ISO 45001:2018 certifications achieved by our company in the last few years and controlled by the most excellent international standards, are the best warranty of the existence of a control system, surveillance and protection of the environment and of the activities carried out by Cromoplastica CMC.

ZERO EMISSIONS

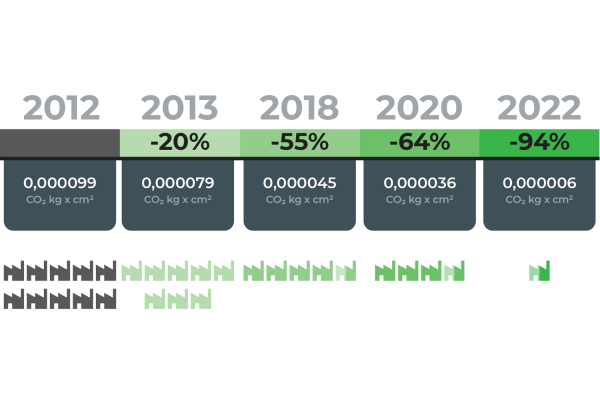

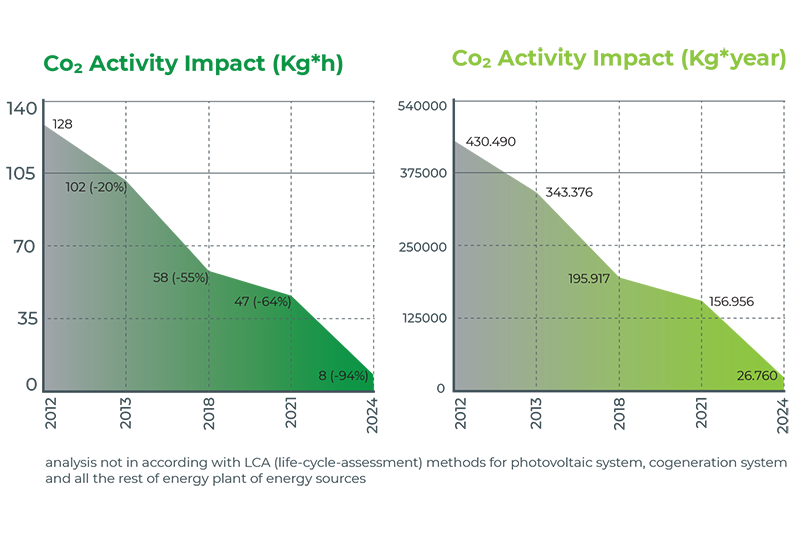

Our goal is to reach within 2030 ZERO CO2 emission either issued or offset, reduced to 0 for all company’s direct activities.

Leaving our planet cleaner than as we found to future generations, is the target we care most.

Here below all the interventions carried out to achieve this goal:

PHOTOVOLTAIC SYSTEM

Since 2012, Photovoltaic system which produces 40% of the total daily electricity consumption with a total CO2 savings of:

METALS RECYCLING

Patented technology (since 2009),with 100% recovery technology for metals contained in solid waste coming from industrial waste treatment process, reconverted into metal, recycled and put back on the market for a total of 1,000 t.

PERMANENT WATER ANALYSIS

Since 2007 installation of an automatic water sampler coming out our purification system which carries out every day 24 analysis of 30 sensitive parameters.

Data are automatically recorded in a sealed black box which is accessible only by specific state authorities.

Our discharge parameters are 10 times lower than drinking water parameters established by law.

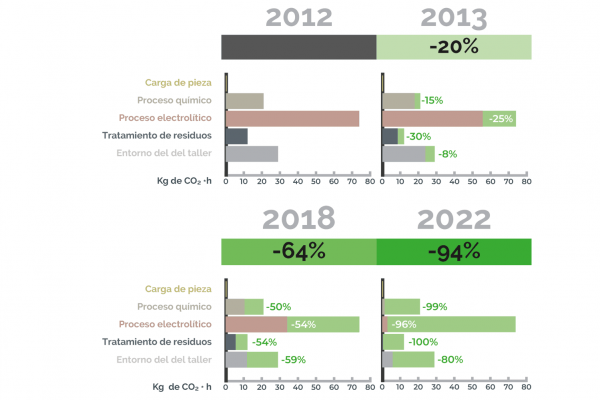

REDUCTION of CO2 EMISSIONS

In 2015 installation of a cogeneration plant which, through the use of natural gas, has allowed self-production of 100% thermal energy and of 35% electricity of the whole company needs.

Adding also electrical energy self-production deriving from the photovoltaic system, Cromoplastica has been able to achieve a self-production equal to 100% thermal energy and 70% electrical energy.

PURIFICATION OF ATMOSPHERIC EMISSIONS

Since 2014 new system for purifying atmospheric emissions, which allowed to reach new standards and a very high level of purity of the air emitted into the atmosphere, with values detected and certified in 2017 by the state control bodies, up to 10 TIMES LOWER than legal limits.

PURIFICATION OF LIQUIDS WASTE

Realization in 2018 of a new automated industrial wastewater purification department, totally manageable by remote without human presence, with a wastewater purification capacity increased by 5 times compared to the previous plant.

In addition to several initiatives already put in place, such as the production of energy with photovoltaic systems and with cogeneration system (CHP Combined Heat and Power Engine) and consumption’s reduction by replacing old machinery with new more performing systems, we report you two following main points:

- in 2018 a giant Bamboo forest of 5 ha was planted, close to our production site (20km), productive in 2021, which will allow the compensation of other 100.000 kg of CO2 / year. This plant species is the most effective in nature to transform CO2 into Oxygen (+35% compared to equal size other plant species)

- From 2022, residual electric energy required for production need will be exclusively purchased from wind or hydroelectric production sites (TUV-certified), with relative supply traceability from production site to Cromoplastica head quarter.

We will refuse Electric Energy deriving from carbon or oil plants, and at the same time we will reject potential supply proposals deriving from nuclear energy, correctly named “Clean Energy” thanks to zero CO2 emissions, but from our point of view, anyway too damaging for environment due to radioactive waste generated and stored underground.

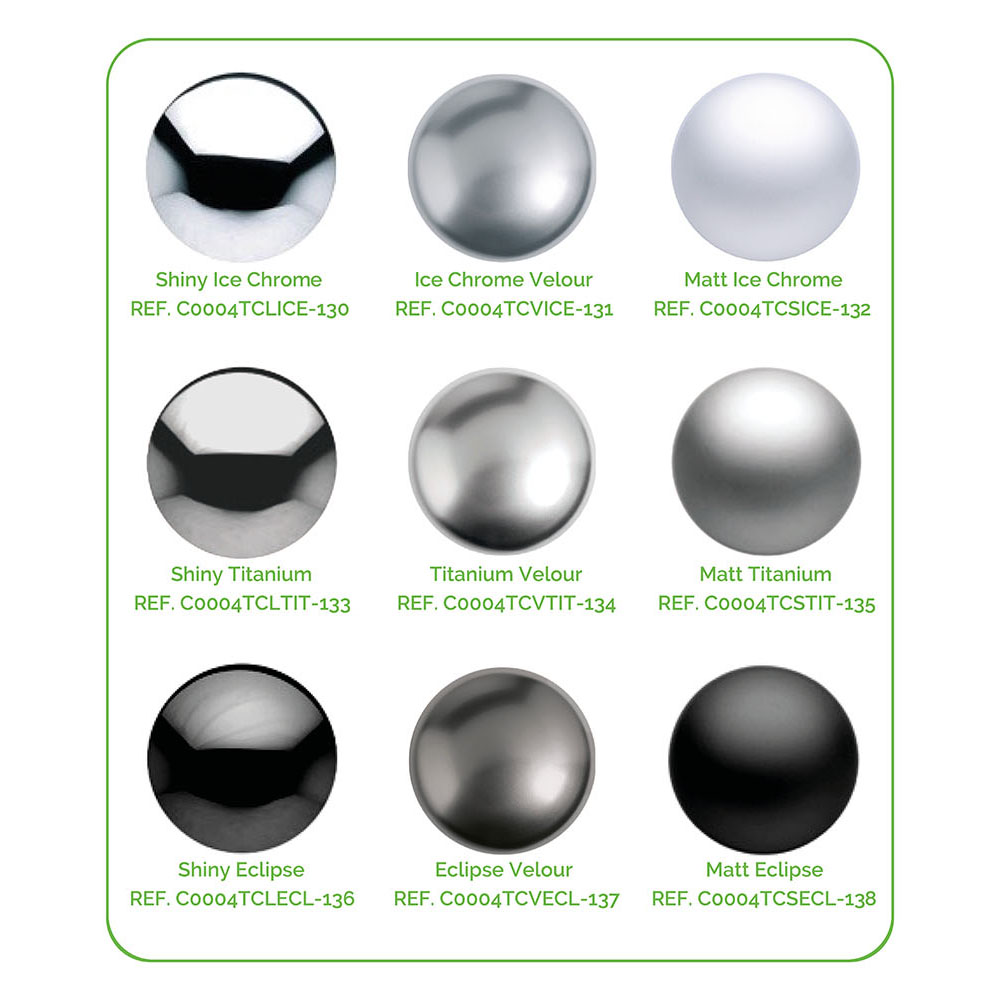

9 trivalent finishes with “Green” technology

Cromoplastica continues its commitment in order to offer to the market an increasingly more and more eco-sustainable technologies maintaining the programmatic commitment of the green deal launched since 2015 (Zero CO2 by 2030).

Click on the image to find out more