Trivalent Finishes: “green” future of Plating on Plastic

Revolution started: “green” future of Plating on Plastic begins now

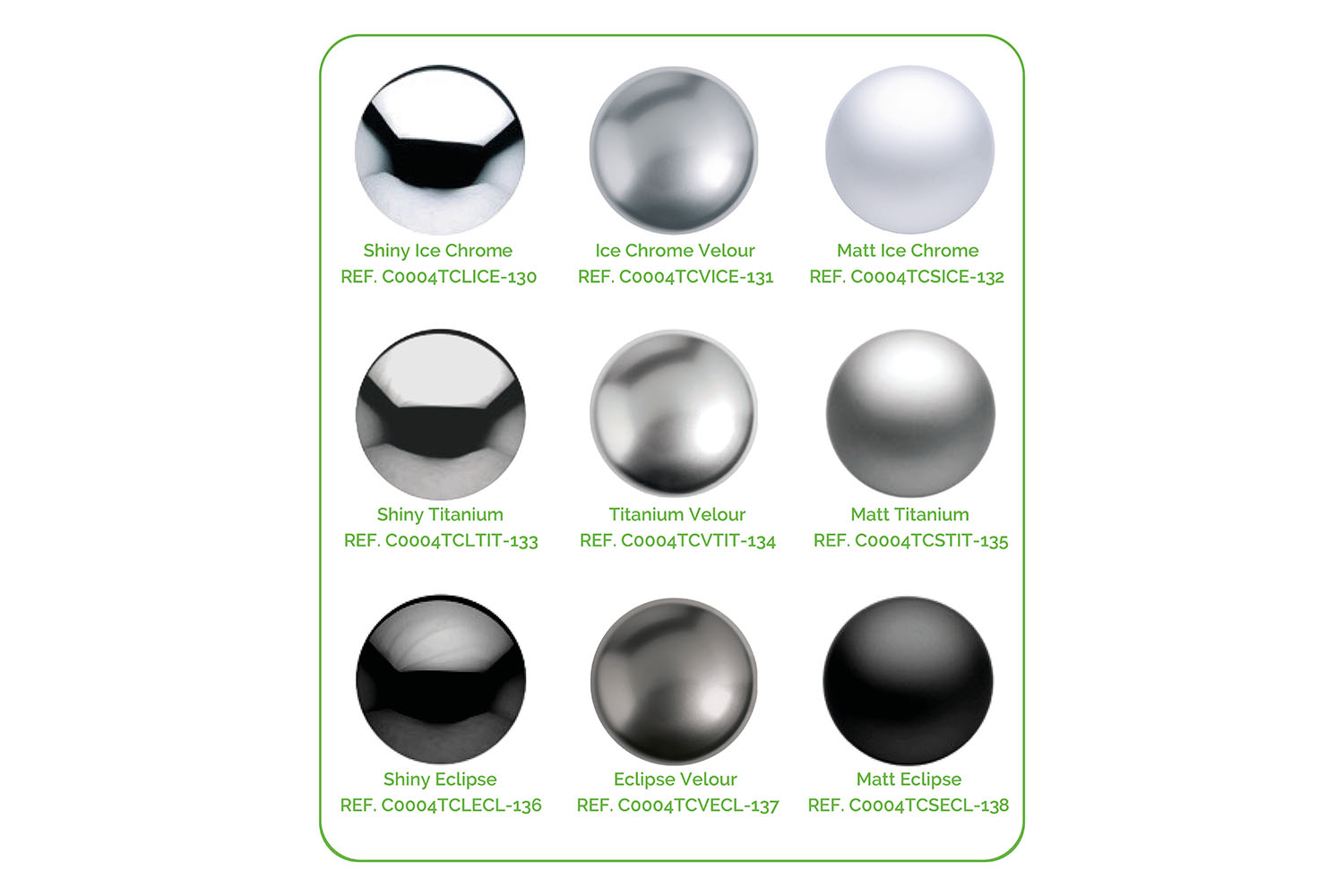

9 New Trivalent Finishes treated with GREEN technology, eco-sustainable

Cromoplastica continues its commitment in order to offer to the market an increasingly more and more eco-sustainable technologies maintaining the programmatic commitment of the green deal launched since 2015 (Zero CO2 by 2030). The main feature is the use of trivalent chromium. The aim is to replace gradually the current chrome finishes, according to market demands and customer needs, with the elimination of hazardous substances and a drastic reduction in CO2 emissions, while maintaining and improving performance and anti-corrosion resistance to salt tests NSS-AASS-CASS, synthetic sweat, etc.

Green Technology

Each new finish has been subjected to the most stringent certification tests required by the main OEMs automotive, home appliance, household electrical goods and perfume-cosmetics

- NSS

- AASS

- CASS

- Thermal Cycles

- Synthetic Sweat

- Resistance to perfumes

- etc

The results guarantee full compliance with the required technical performance.

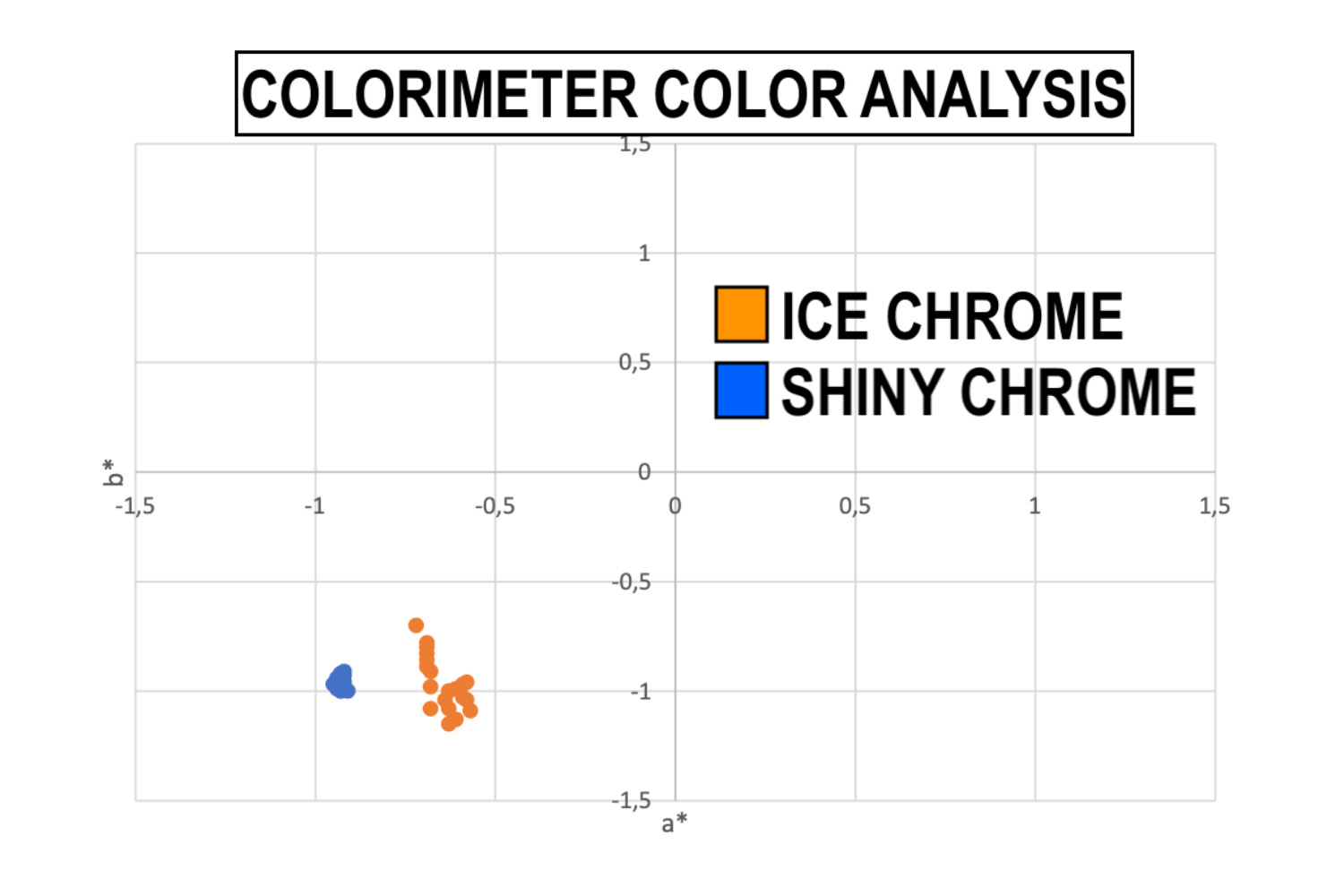

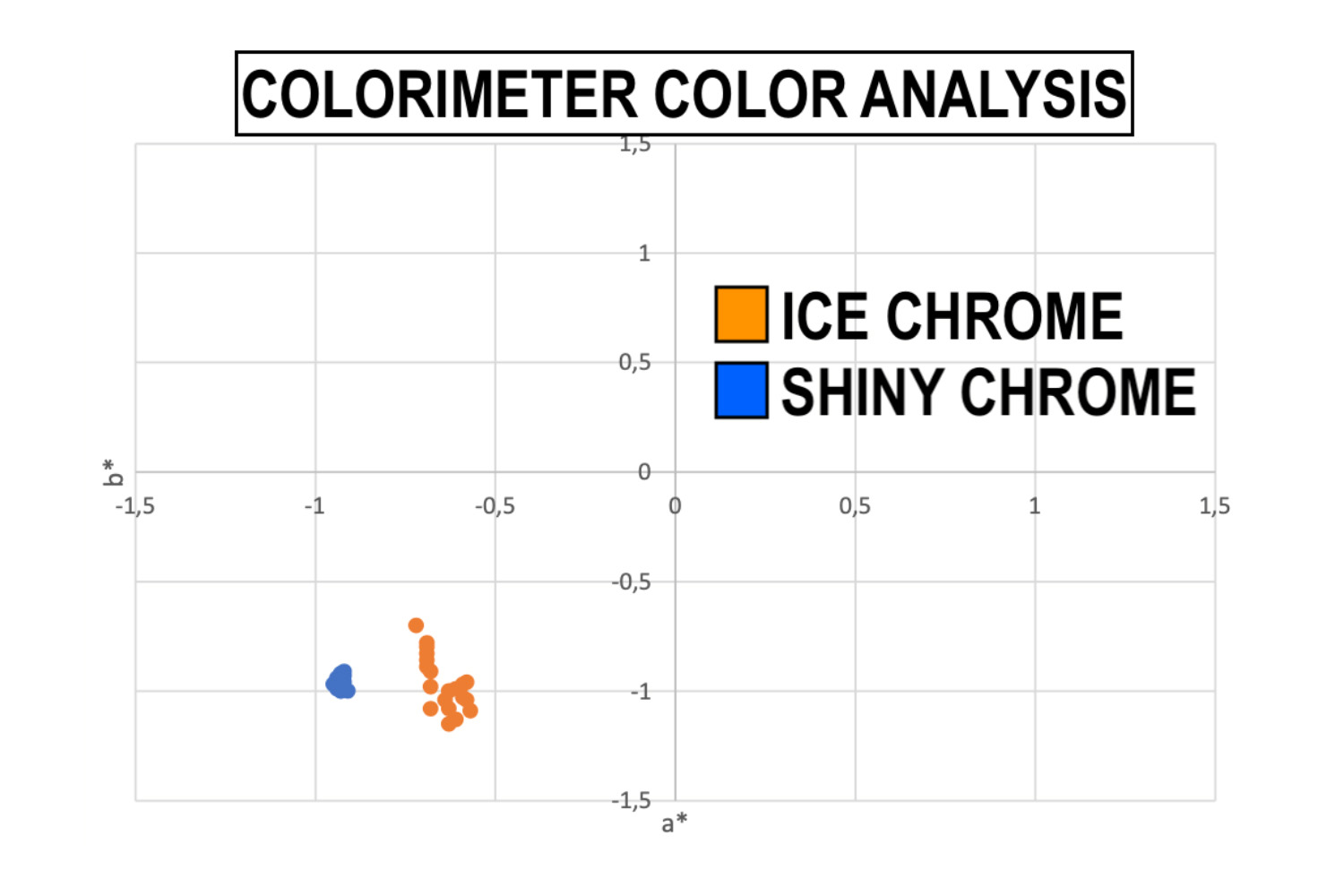

Optic Box

SHINY ICE CHROME Trivalent identical to the current SHINY CHROME Hexavalent

Optic Box shows pieces treated with the new ICE CHROME finish and the old technology in SHINY CHROME, produced with hexavalent chromium.

Any differences between the two processes? NO ONE – NO DIFFERENCE!

COLOR COORDINATES, TECHNICAL PERFORMANCE OF RESISTANCE AND AESTHETIC ASPECT ARE BASICALLY IDENTICAL BETWEEN THE TWO COATINGS.

Please contact us!